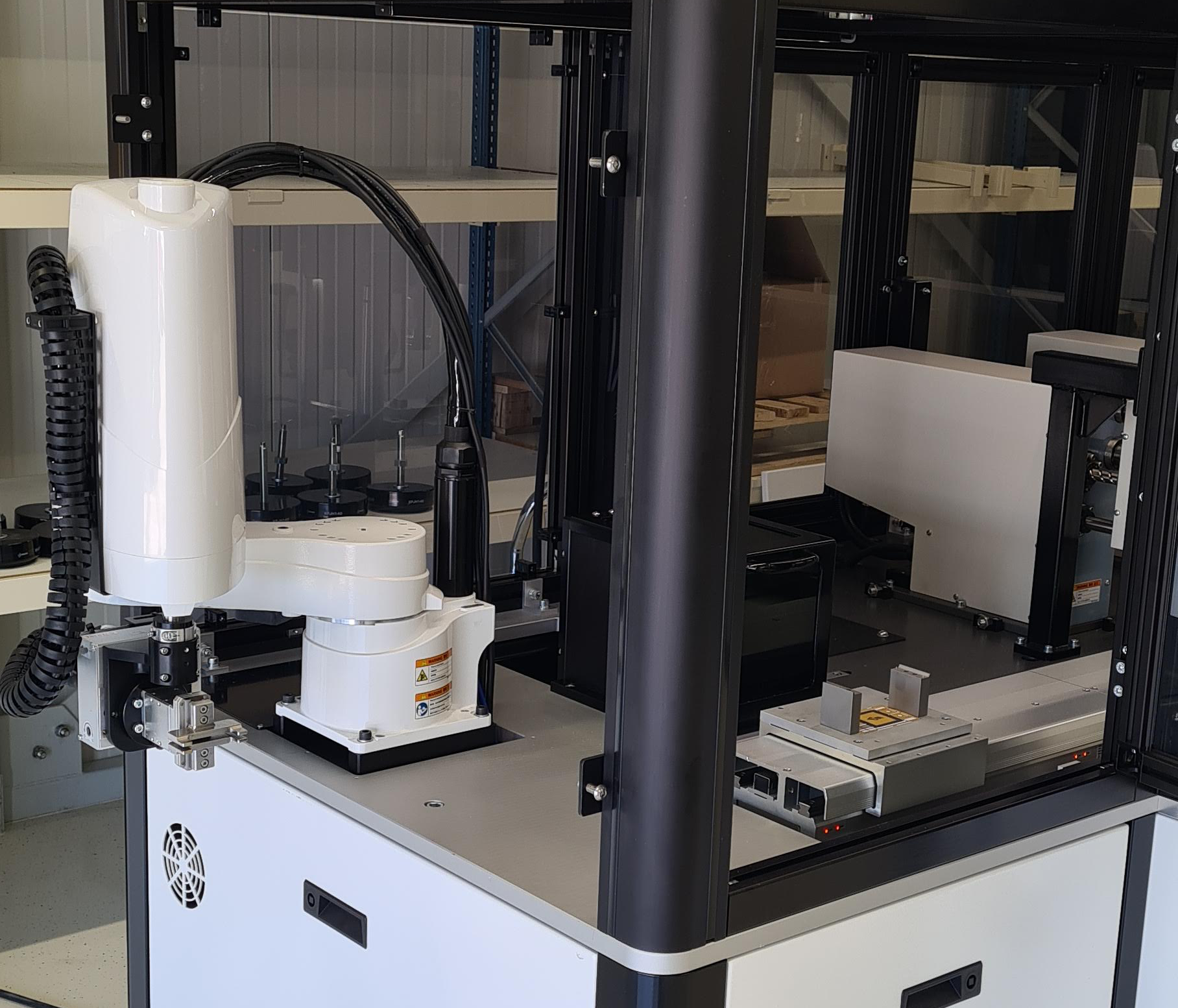

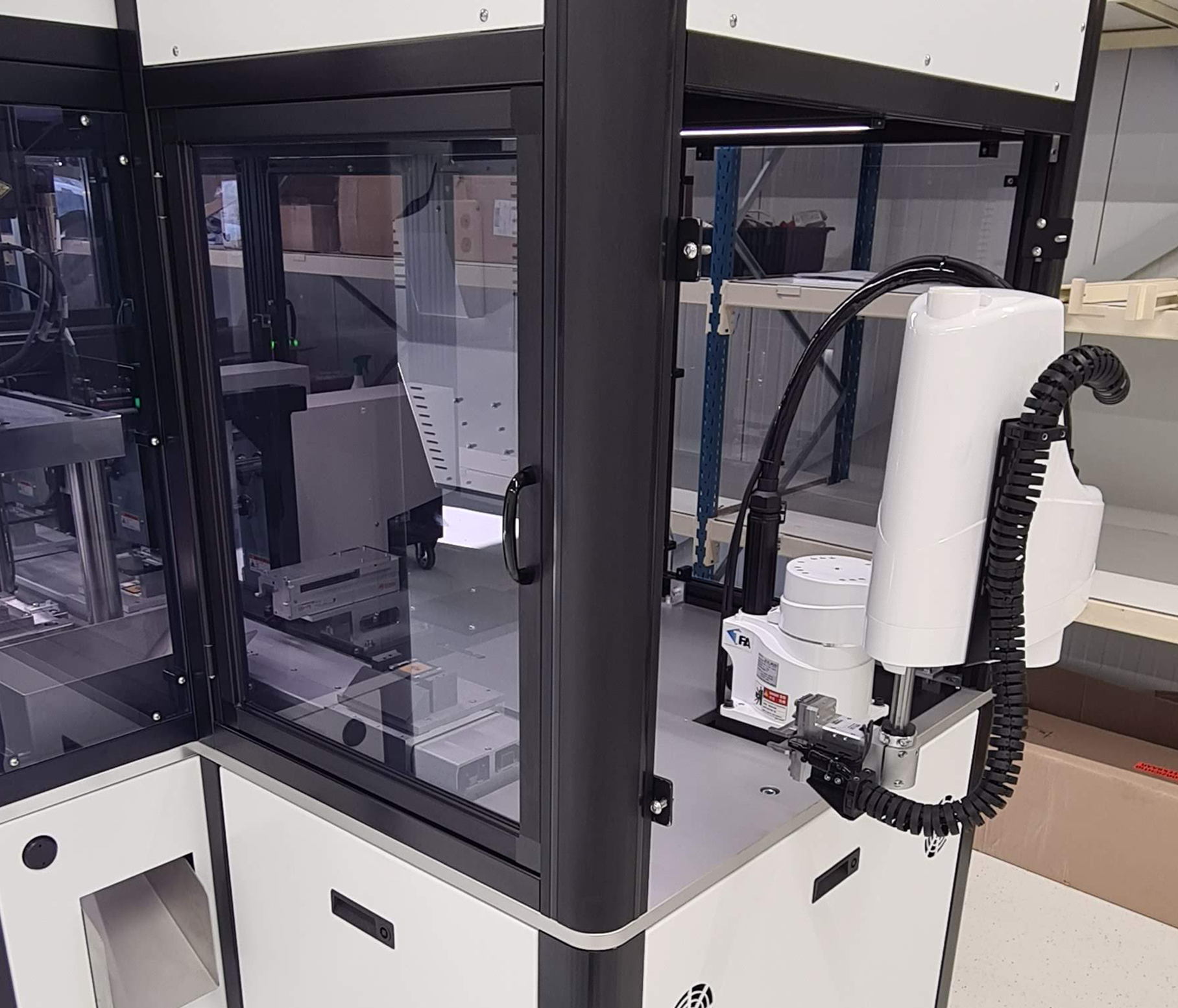

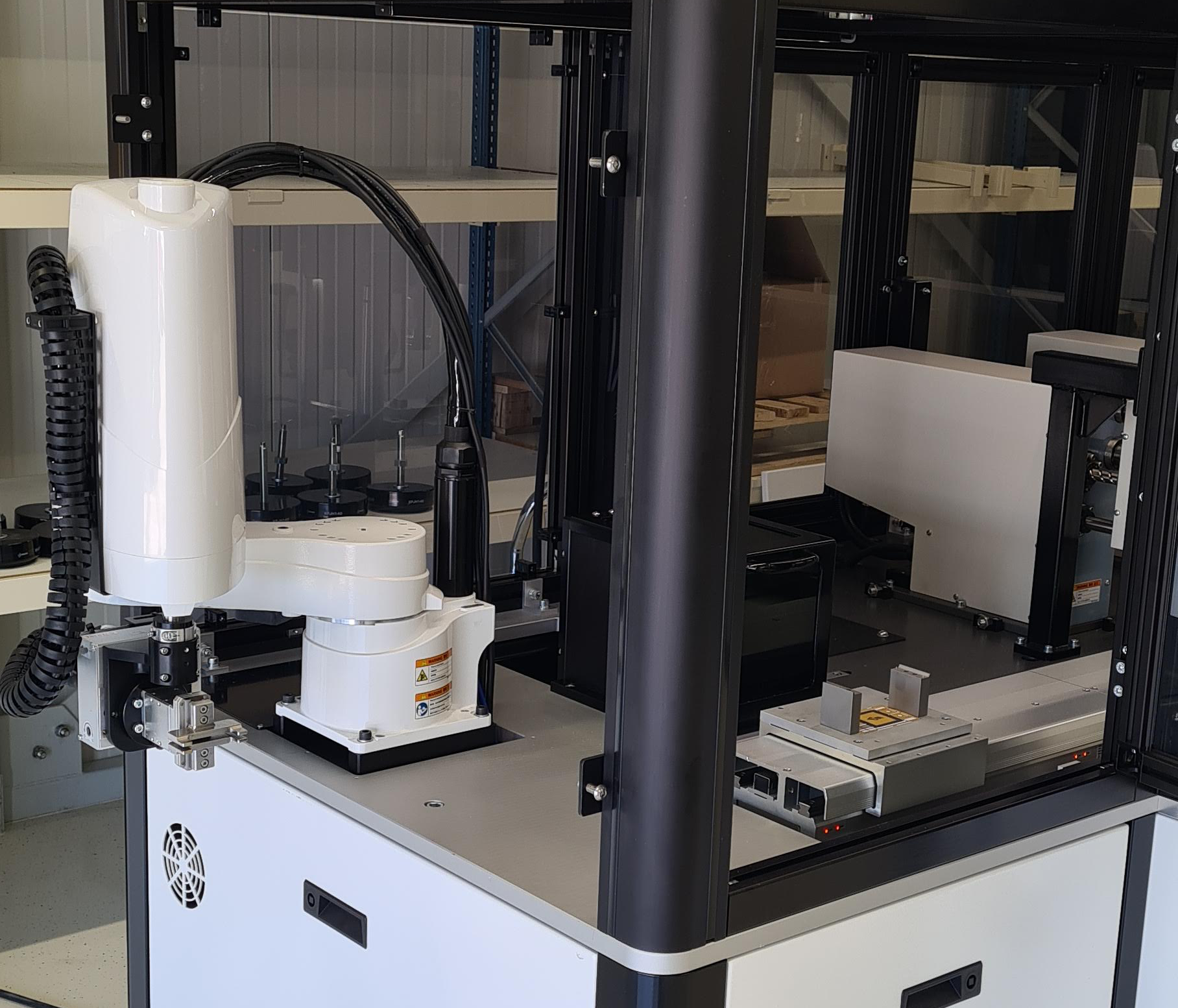

Building on 40 years of semicon toolmaking heritage, Powertrim Technologies has developed its first flagship platform: the Powertrim Flex Line. With its modular architecture, the Flex Line covers the core trim and form processes as well as adjacent process steps like laser marking, laser deflashing, optical inspection, quality control, loading and unloading. Powertrim has developed the Flex Line to enable power electronics manufacturers in automotive, energy and industrial end-markets build predictably quality products at the best total cost.

Powertrim Flex Line is Powertrim’s trim & form machine

- Press force up to 100kN

- Number of press modules is configurable

- Leadframe dimensions: n/a (the Flex Line is for non-leaded modules)

- Speed: 400 to 1200 power modules per hour (depending on process steps/options)

- Product change within 15 minutes

Loading and offloading options:

- Magazines

- Trays

- In-Line

- AGV’s

- SMEMA compatible

Optional modular integrations:

- Barcode/DMC reader

- Laser marking

- Laser deflashing

- Product inspection

- MES integration

The Powertrim Flex Line is a robust, modular and integrated manufacturing solution dedicated to the core process of trim and form for power modules and adjacent process steps

3 press module

3 press module + loading module

3 press module + vision / offloading module

Lasermark / deflash module

Loading / 3 press / offloading module

Lasermark / deflash + 3 press module + vision / offloading module

Loading / 3 press module + vision / offloading module (trays)

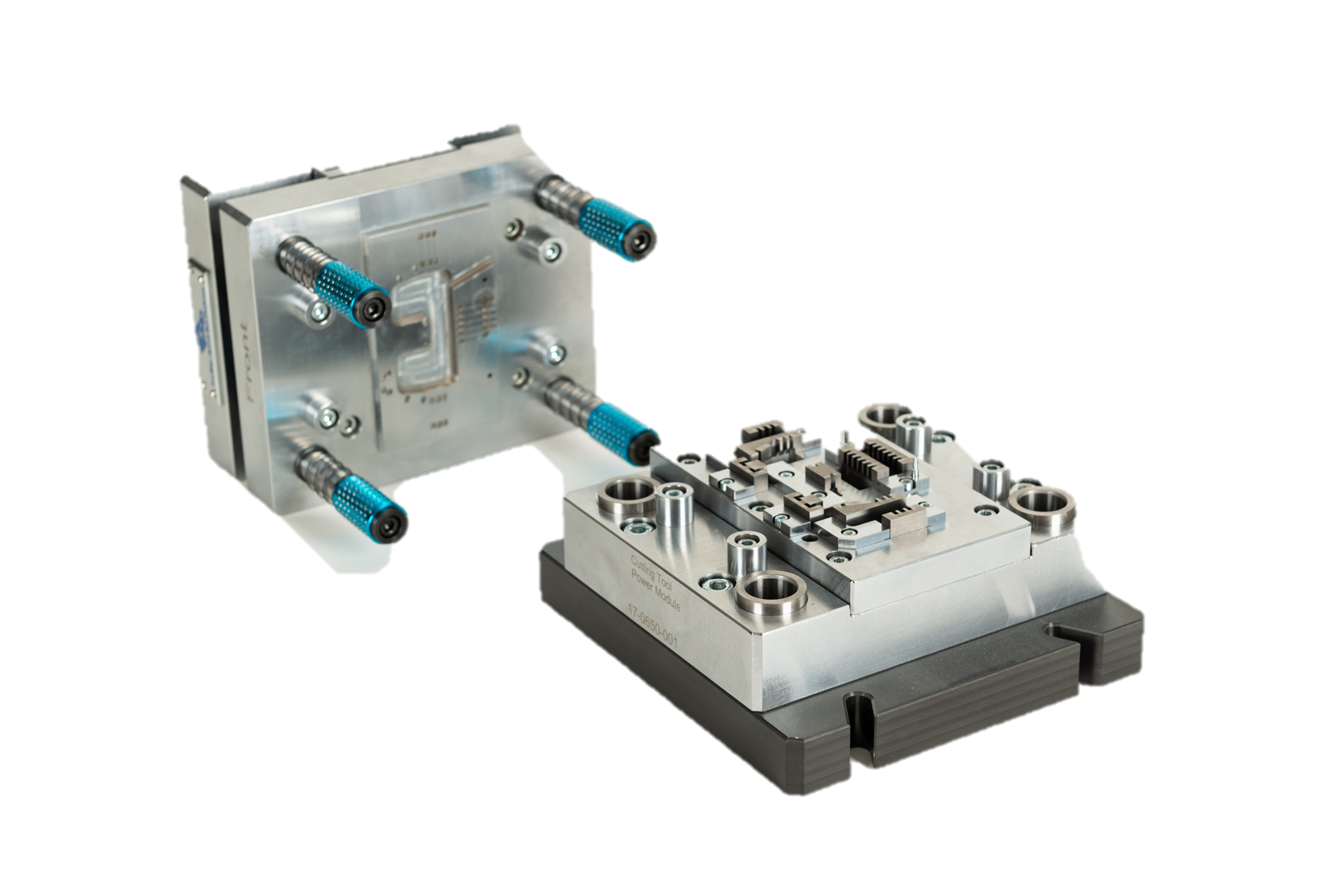

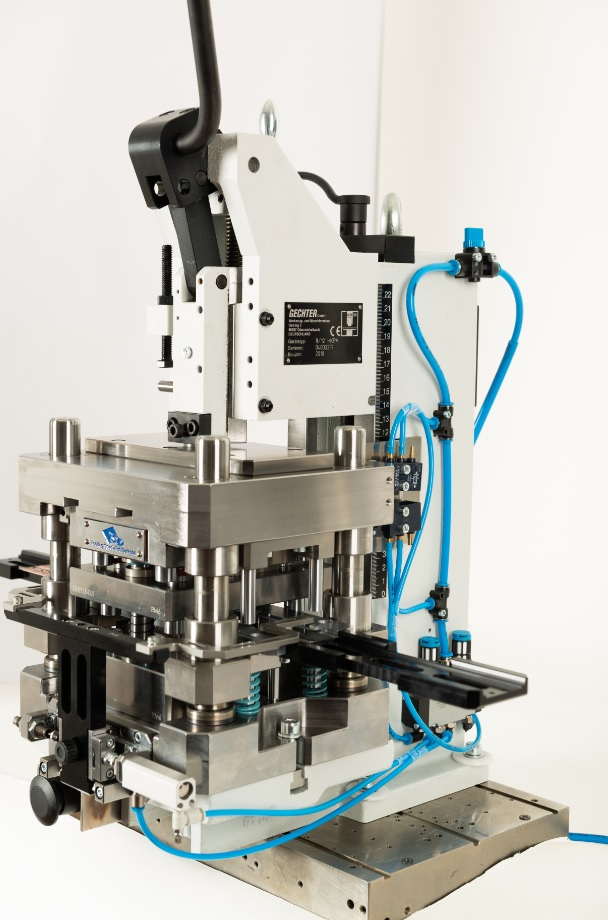

The first step however is designing test tools and process & application development using a manual press that is transferable to the Flex Line

In the design step of new power modules, the tooling needs to be developed. Powertrim Technologies works intimately with toolmakers like TSD (hyperlink: https://www.tooling.nl/en/ and supports customers in this process. The holistic support from Powertrim prevents hand-overs in the value chain and allows for one single point of contact during the complete process from initial design to qualified series production.

Trim and form process development contains 3 steps:

- Dambar cutting step and Deflash step (optional): cutting alongside the package

- Forming step, bending the leads in required shape

- Singulation step: cutting of remaining leadframe and package Tie-bars

Transferable tooling is essential and accelerates the ramp-up for robust production:

- Powertrim-supplied manual tooling can be used in existing Tox Press / Manual press

- After joint successful process & application development, tools can be integrated in the fully automated Flex Line system

Currently available semiconductor Trim & Form equipment is often not suitable for large and individually produced power modules. The typical semiconductor back-end process works with a lead-frame that contains multiple products while a growing number of power modules is manufactured separately as an individual module, requiring individual handling. Moreover, a higher press force is required. The Flex Line is designed to be fully flexible with regards to handling, press force and package outline since there are no standards in power module packaging.

Technology partnership: Boschman Advanced Packaging

Boschman Advanced Packaging technology is market leader in sintering & transfer molding equipment for power modules. Since its inception in 2020, Powertrim is strategically collaborating Boschman Advanced Packaging to support the trim & form activities with (among others):

- POD , leadframe design support

- Rapid prototype tooling for manual production and product qualification

- In-house engineering and manufacturing

- Sample production

- Quality measurements